Competitive PCB Manufacturer

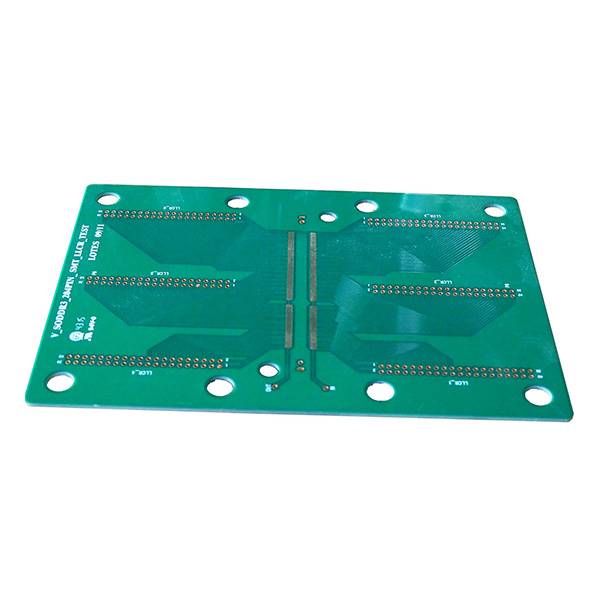

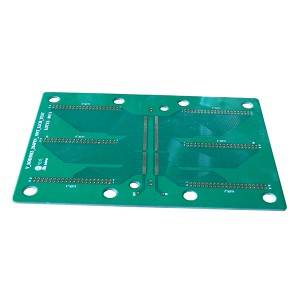

3 oz solder mask plugging ENEPIG heavy copper board

There is no standard definition for Heavy Copper PCB,usually if the copper thickness is more than 30z.

The board is define as thick copper board.

Heavy Copper PCBs are extensively used in the Power Electronics and Power Supply systems where there is a high current requirement or a possibility of quick shooting up of fault current. The increased copper weight can turn a weak PCB board into a solid, reliable, and long-lasting wiring platform and negates the need for an added costlier and bulkier components like Heat sinks, fans, etc.

Thick copper board performance: thick copper board has the best extension performance, not limited by the processing temperature, high melting point can be used oxygen blowing, low temperature is not brittle and other hot-melt welding, and also fire prevention, belongs to non-combustible materials. Copper plates form a strong, non-toxic, passivated coating, even in highly corrosive atmospheric conditions.

Advantages of thick copper plate: Thick copper plate is widely used in various home appliances, high-tech products, military, medical and other electronic equipment. The application of thick copper plate prolong the longer service life of the circuit board which is the core component of electronic equipment products,, and at the same time, it is of great help to simplify the volume of electronic equipment

Heavy Copper PCBs Fabrication

Any PCB manufacturing, whether single-sided or double-sided is composed of copper etching to remove the unwanted copper and plating techniques to add thickness to the planes, pads, and traces and Plated-Through-holes (PTH). The Fabrication of Heavy Copper PCBs is quite similar to the construction of regular FR-4 PCBs but they require special etching and electroplating techniques which increases the thickness of the surface board without altering the layer count. The thick Surface Boards are capable to handle added copper weights due to the specialized techniques that involve high-speed, self plating, and differential or deviation etching.

The normal etching method does not work for Heavy Copper PCBs and creates uneven edge lines and over-etched margins. We use advanced plating techniques to obtain Straight lines and optimal edge margins with negligible undercuts. Our process of additive plating decreases the resistance of copper traces thereby enhancing the heat-conducting capacity and endurance for thermal stress.

The Reduction in thermal resistance improves the heat dissipation capacity of your circuit through thermal convection, conduction, and radiation. Our Fabricators are also focused on thickening the walls of PTH which serves numerous advantages by shrinking the layer count and reducing impedance, foot-print, and overall manufacturing cost. We take great pride in being one of the most affordable and quality Heavy Copper PCBs manufacturers around the globe.

However, these PCBs involves higher cost than regular PCBs as the etching process is vigorous and difficult. Huge amounts of Copper need to be eliminated during the Etching process. Also, the lamination process demands the utilization of Prepreg with high resin content for filling the spaces between the copper traces. So, the cost of manufacturing is higher than Regular PCBs. Nevertheless, we employ a combination of Blue Bar Method and Embedded Copper method for providing you a superior board at the best price.

Application of Heavy Copper PCBs

We manufacture and supply these PCBs where there is frequent or sudden exposure to strong current and augmented temperature. Such extreme levels are enough to damage a regular PCB and call for Heavy Copper requirement which also lowers the layer count, offers lower impedance, and enables smaller footprint and huge cost savings. Below are some areas and d applications that Heavy Copper PCBs are used in:

• Power Distribution systems

• Power Amplifier Modules

• Automotive Power Distribution Junction Boxes

• Power Supplies for Radar Systems

• Welding Equipment

• HVAC Systems

• Nuclear Power Applications

• Protection and Overload Relays

• Railway Electrical Systems

• Solar Panel Manufacturers

In recent years, the demand for these PCBs has increased in Automotive, Military, computer, and industrial control applications. Kangna has decades of experience in producing Heavy Copper PCBs of supreme quality. Our Skilled Engineers are devoted to meet the highest standards and create Premium Boards that meet your performance expectations and profitability goals. We understand that Heavy Copper PCB designing comes with additional complexities and hence, we closely address all questions and concerns before proceeding with the production.

What makes us special is that our developed boards pass through various cycles of quality check before it is delivered to our clients. Our in-house quality control department guarantees the quality of the Heavy Copper PCBs and makes sure that the final product meets the finest quality with minimal to no risk of circuit failure.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.