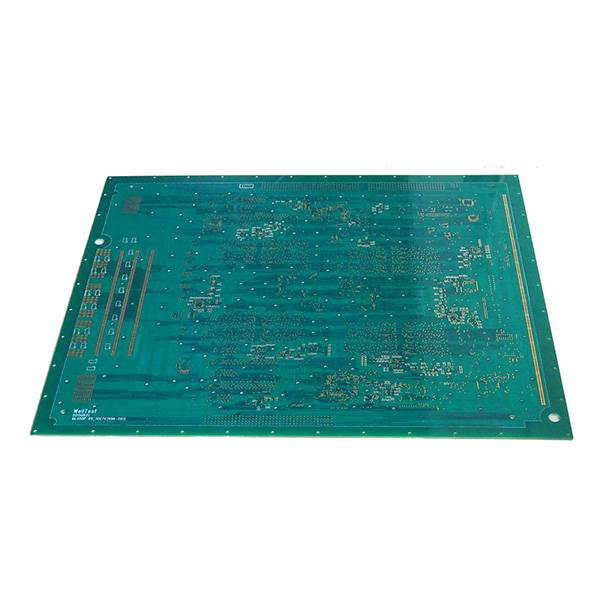

Competitive PCB Manufacturer

fast multilayer High Tg Board with immersion gold for modem

Material type: FR4 Tg170

Layer count: 4

Min trace width/space: 6 mil

Min hole size: 0.30mm

Finished board thickness: 2.0mm

Finished copper thickness: 35um

Finish: ENIG

Solder mask color: green``

Lead time: 12 days

When the temperature of high Tg circuit board rises to a certain region, the substrate will change from "glass state" to "rubber state", and the temperature at this time is called the glass transition temperature (Tg) of the plate. In other words, Tg is the highest temperature (℃) at which the substrate remains rigid. That is to say, ordinary PCB substrate material at high temperature not only produces softening, deformation, melting and other phenomena, but also shows a sharp decline in mechanical and electrical properties (I don't think you want to see their products appear this case).

General Tg plates are over 130 degrees, high Tg is generally more than 170 degrees, and medium Tg is about more than 150 degrees.

Usually, The PCB with Tg≥170℃ is called high Tg circuit board.

The Tg of the substrate increases, and the heat resistance, moisture resistance, chemical resistance, stability resistance and other characteristics of the circuit board will be improved and improved. The higher the TG value is, the better the temperature resistance performance of the plate will be. Especially in lead-free process, high TG is often applied.

High Tg refers to high heat resistance. With the rapid development of the electronic industry, especially the electronic products represented by computers, towards the development of high function, high multilayer, the need for PCB substrate material higher heat resistance as an important guarantee. The emergence and development of high density installation technology represented by SMT and CMT makes PCB more and more dependent on the support of high heat resistance of substrate in terms of small aperture, fine wiring and thin type.

Therefore, the difference between ordinary FR-4 and high-TG FR-4 is that in the thermal state, especially after hygroscopic and heated, the mechanical strength, dimensional stability, adhesion, water absorption, thermal decomposition, thermal expansion and other conditions of the materials are different. High Tg products are obviously better than ordinary PCB substrate materials. In recent years, the number of customers requiring high Tg circuit board has increased year by year.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.