Competitive PCB Manufacturer

professional factory for Prototype PCB Assembly - Low Volume medical PCB SMT Assembly – Kangna

professional factory for Prototype PCB Assembly - Low Volume medical PCB SMT Assembly – Kangna Detail:

SMT is the abbreviation for Surface Mounted Technology, the most popular Technology and process in the electronic assembly industry. Electronic circuit Surface Mount Technology (SMT) is called Surface Mount or Surface Mount Technology. It is a kind of Circuit assembly technology that installs leadless or short lead surface assembly components (SMC/SMD in Chinese) on the surface of Printed Circuit Board (PCB) or other substrate surface, and then welds and assembles by means of reflow welding or dip welding.

In general, the electronic products we use are made of PCB plus various capacitors, resistors and other electronic components according to the circuit diagram, so all kinds of electrical appliances need various SMT chip processing technology to process.

SMT basic process elements include: screen printing (or dispensing), mounting (curing), reflow welding, cleaning, testing, repair.

1. Screen printing: The function of screen printing is to leak the solder paste or patch adhesive onto the PCB’s solder pad to prepare for the welding of components. The equipment used is screen printing machine (screen printing machine), located at the front end of SMT production line.

2. Glue spraying: It drops glue to the fixed position of PCB board, and its main function is to fix components to the PCB board. The equipment used is the dispensing machine, located at the front end of SMT production line or behind the testing equipment.

3. Mount: Its function is to install surface assembly components accurately to the fixed position of PCB. The equipment used is SMT placement machine, located behind the screen printing machine in THE SMT production line.

4. Curing: Its function is to melt the SMT adhesive so that surface assembly components and PCB board can be firmly adhered together. The equipment used is curing furnace, located at the back of SMT SMT production line.

5. Reflow welding: the function of reflow welding is to melt the solder paste, so that surface assembly components and PCB board firmly stick together. The equipment used is reflow welding furnace, located in the SMT production line behind the SMT placement machine.

6. Cleaning: The function is to remove the welding residue such as flux on the assembled PCB that is harmful to human body. The equipment used is the cleaning machine, the position can not be fixed, can be online, or not online.

7. Detection: It is used to detect the welding quality and assembly quality of the assembled PCB. The equipment used includes magnifying glass, microscope, on-line testing instrument (ICT), flying needle testing instrument, automatic optical testing (AOI), X-ray testing system, functional testing instrument, etc. The location can be configured in the appropriate part of the production line according to the requirements of the inspection.

8.Repair: it is used to rework the PCB that has been detected with faults. The tools used are soldering irons, repair workstations, etc. The configuration is anywhere in the production line.

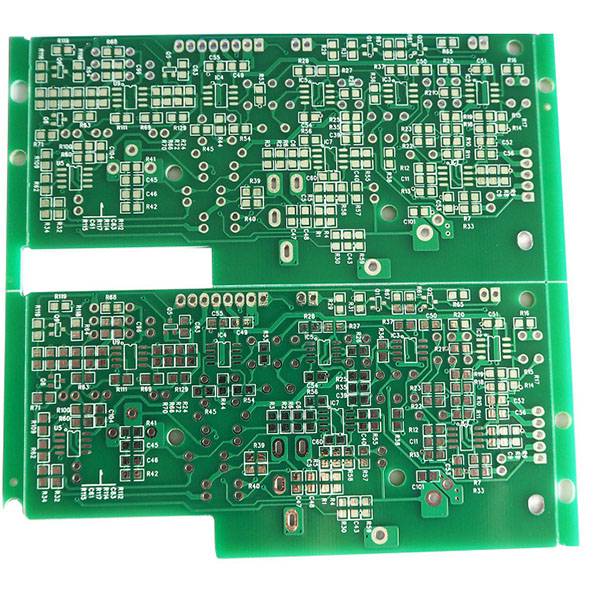

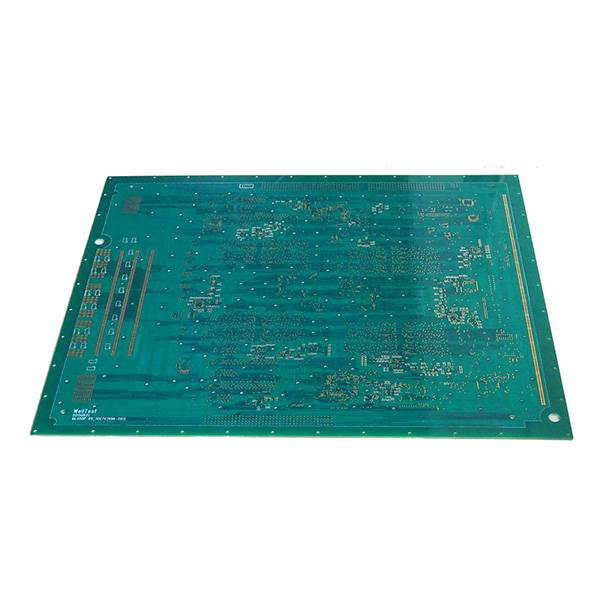

Product detail pictures:

Related Product Guide:

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for professional factory for Prototype PCB Assembly - Low Volume medical PCB SMT Assembly – Kangna , The product will supply to all over the world, such as: Las Vegas, Bangladesh, Ecuador, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business in Kenya and overseas. Immediate and professional after-sale service supplied by our consultant group has happy our buyers. Thorough Info and parameters from the merchandise will probably be sent for you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Kenya for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.