Competitive PCB Manufacturer

PriceList for Flex PCB Assembly - 1.6mm fast prototype standard FR4 PCB – Kangna

PriceList for Flex PCB Assembly - 1.6mm fast prototype standard FR4 PCB – Kangna Detail:

Material type: FR-4

Layer count: 2

Min trace width/space: 6 mil

Min hole size: 0.40mm

Finished board thickness: 1.2mm

Finished copper thickness: 35um

Finish: lead free HASL

Solder mask color: green

Lead time: 8 days

Printed circuit board is an important electronic component, is the support body of electronic components, is the carrier of electrical connection of electronic components. Because it is made by electronic printing, it is called “printed” circuit board.

Almost every electronic device, from electronic watches and calculators to computers, communication electronic devices and military weapon systems, USES printed boards in order to make the electrical interconnections between the components as long as there are electronic components such as integrated circuits. The printed circuit board is composed of an insulating base plate, connecting wires and a soldering plate for assembling welded electronic components. It has the dual functions of conducting lines and insulating base plate. It can replace the complex wiring, realize the electrical connection between each component in the circuit, not only simplify the assembly of electronic products, welding work, reduce the traditional way of wiring workload, greatly reduce the labor intensity of workers; It also reduces the volume of the whole machine, reduces the product cost, and improves the quality and reliability of electronic equipment. Printed circuit boards have good product consistency and can be standardized to facilitate mechanization and automation in the production process. At the same time, the whole printed circuit board after assembly debugging can be used as an independent spare part to facilitate the exchange and maintenance of the whole machine products. At present, printed circuit board has been widely used in the manufacture of electronic products

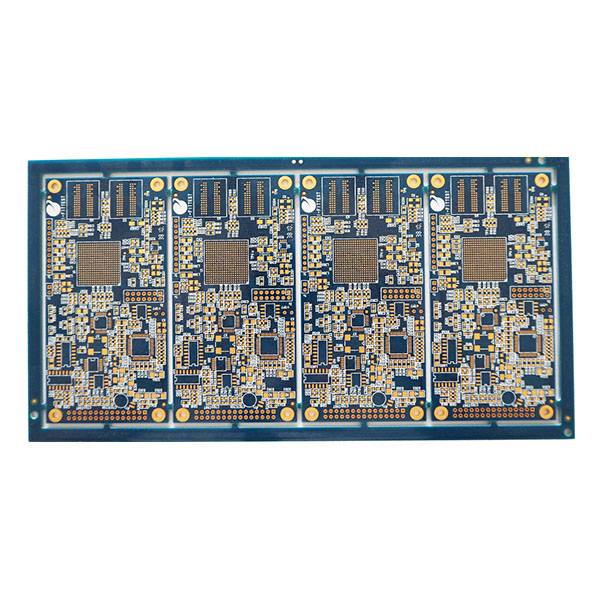

According to the number of circuit layers, it is classified into single panel, double panel and multilayer panel. Common laminates are generally 4 or 6 layers, and complex layers can reach dozens of layers.

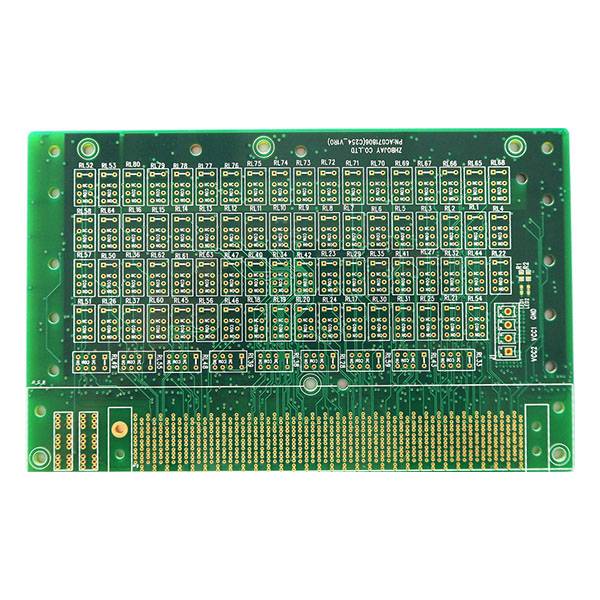

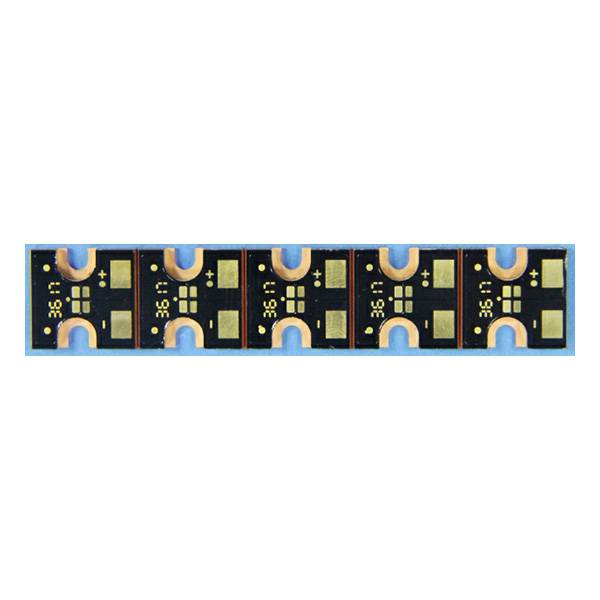

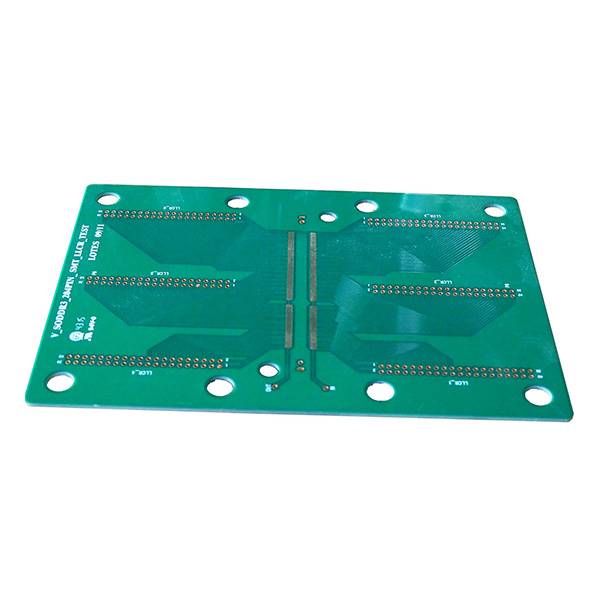

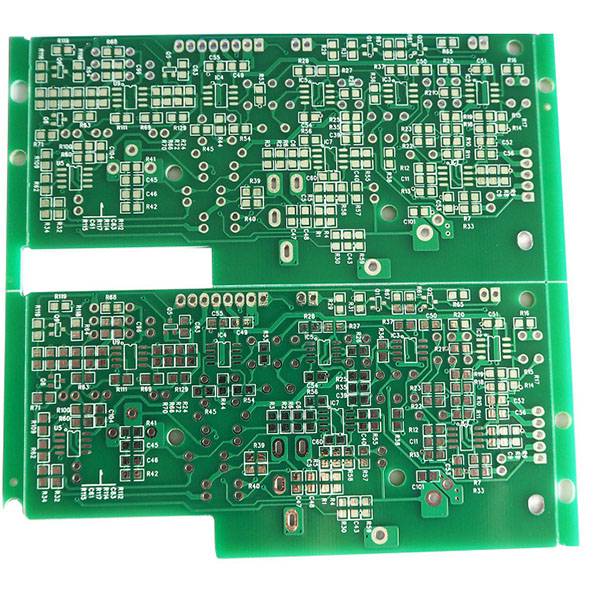

Product detail pictures:

Related Product Guide:

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for PriceList for Flex PCB Assembly - 1.6mm fast prototype standard FR4 PCB – Kangna , The product will supply to all over the world, such as: Guatemala, Azerbaijan, Oman, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.